In PartOne of this article, I presented some reasons why shops should consider material-specific taps. This section will explore some of the features to look for in one. Before diving in, however, it’s essential to recognize the difference between plug and bottoming taps.

Taming Tapping, Part II: Why a One Size Fits All Mentality Doesn't Always Cut the Mustard

Oct 13, 2021 5:12:58 PM / by Mark Hatch posted in tapping, taps, metalworking, Inconel, alloys, thread milling

Taming Tapping, Part I: Why a One Size Fits All Mentality Doesn't Always Cut the Mustard

Sep 8, 2021 10:12:18 AM / by Mark Hatch posted in tapping, taps, metalworking, Inconel, alloys

Drilling has long been recognized as one of the most common yet most challenging of all metalworking operations. Tapping is even tougher. Aside from problems with chip evacuation and potential coolant starvation, there's the sheer amount of metal being removed relative to the available space for the cutting tool.

Hundreds of New Products, Expanded Material Options, Game-Changing Innovation

Reputation is everything. You may know us best for our taps, but for over a century EMUGE-FRANKEN has been developing and manufacturing milling tools — a wide range of solid carbide and HSS end mills, PCD and CBN inserts, and milling cutters with indexable inserts. In 2016 EMUGE-FRANKEN pioneered the development of Circle Segment Technology, introducing game-changing advancements for milling applications.

Today, we are excited to announce the launch of our first North American end mill catalog. The NEW Catalog 420 features thousands of new items ranging from general application to material-specific cutters. And, just as you would expect from EMUGE-FRANKEN, our full end mill program is supported by a national team of technical sales and in-house milling application and programming experts.

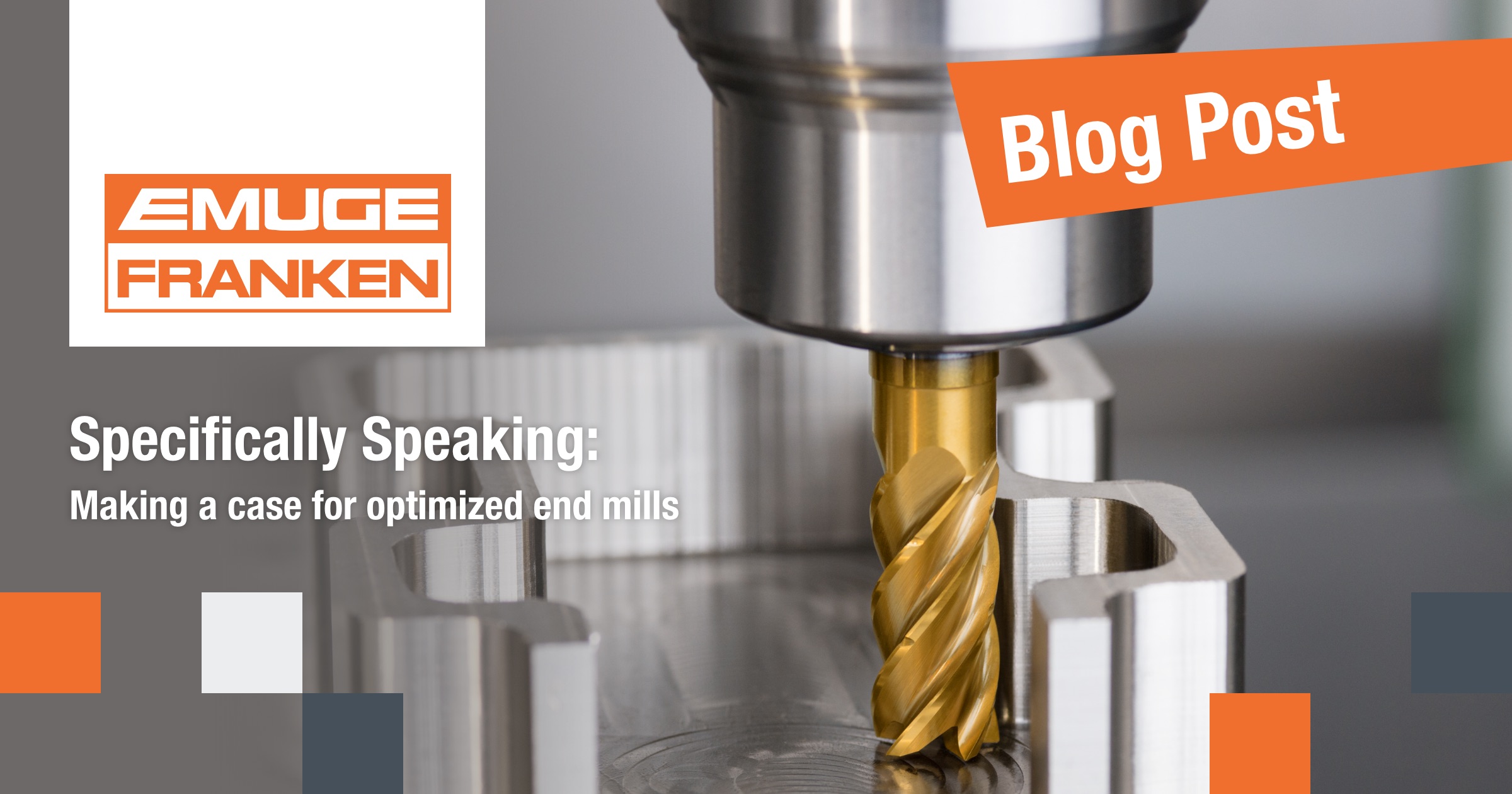

Specifically Speaking: Making a case for optimized end mills

Jun 3, 2021 8:47:44 AM / by Dan Doiron posted in End Mills

For job shops and others machining a wide variety of materials, general-purpose end mills offer a nice balance between performance, tool life, and inventory costs. Yet some metals are either so difficult to cut or machined in large enough quantities that only the very best combination of carbide, coating, and geometry will do.

Perhaps you’re on the fence over shrink fit vs. hydraulic toolholders. Or maybe your shop still uses Weldon side-lock holders and wonders why tool life is less than spectacular, or struggles with pull-out no matter how hard you tighten that collet chuck. You’re not alone. Many shops are using the same toolholder technology they started out with decades ago and are reluctant to invest in something new, or are confused over which direction they should go.

Achieving 10X Better Tool Life in Demanding Aerospace Applications with ZGF-S-CUT Thread Mills

Feb 10, 2021 1:11:24 PM / by Marlon Blandon

Materials that require threads to be thread milled (versus tapped) are usually very complex alloys created for components or parts designed for long term use.

Circle for Success: Part 3

Feb 4, 2021 1:44:48 PM / by Dan Doiron and Evan Duncanson posted in 5-Axis Milling, Circle Segment, Medical Device Manufacturing, Power Generation, End Mills, Dynamic Milling, Aerospace, Mold and Die, Accelerated Finishing

This is part three in a three-part blog series on Circle Segment Tools

Circle for Success: Part 2

Dec 17, 2020 5:10:52 PM / by Dan Doiron and Evan Duncanson posted in 5-Axis Milling, Circle Segment, Medical Device Manufacturing, Power Generation, End Mills, Dynamic Milling, Aerospace, Mold and Die, Accelerated Finishing

This is part two in a three-part blog series on Circle Segment Tools

Circle for Success

Nov 16, 2020 1:27:06 PM / by Dan Doiron and Evan Duncanson posted in 5-Axis Milling, Circle Segment, Medical Device Manufacturing, Power Generation, End Mills, Dynamic Milling, Aerospace, Mold and Die