As we approach Thanksgiving, we’re filled with gratitude for a year marked by achievements, innovation, and celebration at EMUGE-FRANKEN.

A Season of Gratitude: Reflecting on 2024 at EMUGE-FRANKEN USA

Nov 18, 2024 10:57:57 AM / by Angela Marcotte

Machine Heat Resistant Super Alloys Up to 400% Faster with Ceramic End Mills

Aug 7, 2023 4:13:41 PM / by Scott Lowe posted in End Mills, Aerospace

Cera-Cut is a groundbreaking innovation specifically designed to increase productivity by significantly decreasing rough milling time in heat-resistant superalloy (HRSA) materials. This high-performance technology greatly benefits the aero-engine industry, where HRSA materials are prevalently used due to the extreme heat generated within jet engines.

I have personally tested this with customers, and I reckon it has to be the most robust ceramic milling cutter on the market. If saving time roughing heat-resistant super alloys is of utmost importance to your shop, then this post is for you!

KNOW the DRILL

Jun 1, 2023 9:51:31 AM / by Marlon Blandon posted in thread milling, Taps, Drill, Drilling

Drilling is a critical metalworking process, especially in preparing the hole for tapping and threading. Reviewing some tips before selecting a drilling tool can save time and mitigate challenges once in production. One of the most important considerations is whether to use a multipurpose or application-specific drill. The answer depends on several factors, including the material you are drilling, the depth of the hole you need to create, the level of accuracy, and the volume of parts for your application(s).

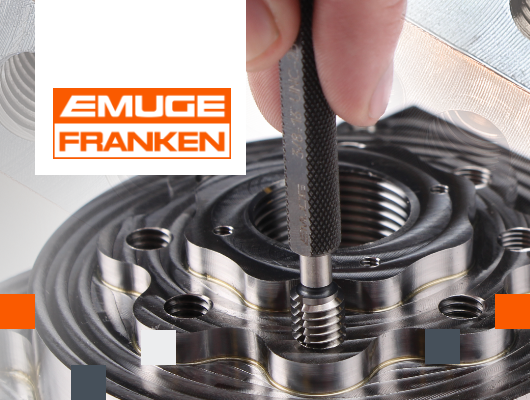

Why a High-Quality Thread Gage Matters

May 25, 2023 8:35:40 AM / by EMUGE-FRANKEN USA posted in tapping, taps, metalworking, Inconel, alloys, thread milling, Self Locking Threads, Gage

In the world of manufacturing and engineering, precision is crucial. Threaded components are used in a wide variety of applications, from automotive and aerospace to medical devices and consumer products. Ensuring the accuracy and quality of these components is essential for the proper functioning and safety of the final product. That's where a high-quality thread gage comes in.

Fixing Fasteners: Why Threads Come Loose and What to Do About It

Aug 17, 2022 12:43:19 PM / by Mark Hatch posted in Medical Device Manufacturing, Aerospace, tapping, taps, metalworking, Inconel, alloys, thread milling, Self Locking Threads

Part Four: The Screw Thread Solution

So far in Fixing Fasteners, we’ve provided a short introduction to screw threads and threaded fasteners, along with some options for making them stay put. Part Three described one of the most efficient systems for accomplishing this, the Detroit Tool Company's wedge ramp thread design. The patent for that simple yet ingenious invention has long since run out and is now represented by two companies—Stanley Engineered Products with its SpiralockTM brand and its alternative, Emuge-Franken’s Self-Lock™ thread locking technology.

Fixing Fasteners: Why Threads Come Loose and What to Do About It

Aug 17, 2022 12:42:41 PM / by Mark Hatch posted in Medical Device Manufacturing, Aerospace, tapping, taps, metalworking, Inconel, alloys, thread milling, Self Locking Threads

Part Three: A Valiant Attempt

In the previous two segments of Fixing Fasteners, we reviewed the basics of thread design and provided some brief descriptions of the industry's various attempts to secure fasteners. This section will discuss a more practical approach to the latter. In 1979, the Detroit Tool Company made a simple modification to a standard thread profile. They called it SpiralockTM, and it soon became quite popular for use in mission-critical applications by military and aerospace manufacturers, and eventually the medical industry.

Fixing Fasteners: Why Threads Come Loose and What to Do About It

Aug 17, 2022 12:39:32 PM / by Mark Hatch posted in Medical Device Manufacturing, Aerospace, tapping, taps, metalworking, Inconel, alloys, thread milling, Self Locking Threads

Part Two: As the Screw Turns

In Part One of Fixing Fasteners, we offered a brief overview of screws and thread manufacturing, their different classes of fit, and some comments on the importance of proper tolerancing and gaging when machining screw threads. Adhering to these guidelines is the first step toward making strong, dependable fasteners. However, even the highest quality screw, nut, or bolt can come loose unexpectedly (often at the worst possible time) when subjected to vibration and other forces.

That's because threaded fasteners are intended to come apart. It’s an unfortunate truth (or a fortunate one, depending on your perspective) that all machinery and other mechanical assemblies must be constructed in a manner that allows them to be serviced, refilled, and repaired. If not, they could simply be welded together, eliminating the need for threads entirely.

Fixing Fasteners: Why Threads Come Loose and What to Do About It

Aug 17, 2022 12:39:02 PM / by Mark Hatch posted in Medical Device Manufacturing, Aerospace, tapping, taps, metalworking, Inconel, alloys, thread milling, Self Locking Threads

Part One: Threads on Parade

This four-part series will discuss threaded fasteners, why they come loose, and how engineers and product designers can prevent this unfortunate, sometimes dangerous event. We’ll preface it by saying that Emuge-Franken is a cutting tool manufacturer with more than a century of experience in this area. The company invented the first spiral point tap for producing internal threads in 1921 and has since developed some of the highest-quality drills, end mills, and threading products on the market. As you’ll soon see, they have also addressed the problem just mentioned—fasteners coming loose—with a comprehensive and innovative solution.

Three Reasons to Give Thread Milling a Chance

Jan 28, 2022 5:16:51 PM / by Marlon Blandon posted in Tool Holders, thread milling, Multi Thread Mill

Although EMUGE is known for its high-quality line of tapping products, there are times when thread milling is a better choice. In this post, we’ll explore a few of the key differences between the two, and when to use one over the other.

For those engaged in high-mix, low-volume machining, versatility (mostly) rules

Aluminum one day, titanium the next, low-carbon steel the day after that. When you have no idea what’s coming down the pike, it's obvious that you need cutting tools able to survive whatever you throw their way. But is survival enough? Is it better to sacrifice some modicum of performance to avoid switching to a material-specific cutting tool, or to keep the tool crib inventory to the bare minimum by going to a more general-purpose grade of carbide and tool geometry?