Drilling is a critical metalworking process, especially in preparing the hole for tapping and threading. Reviewing some tips before selecting a drilling tool can save time and mitigate challenges once in production. One of the most important considerations is whether to use a multipurpose or application-specific drill. The answer depends on several factors, including the material you are drilling, the depth of the hole you need to create, the level of accuracy, and the volume of parts for your application(s).

Marlon Blandon

Marlon Blandon is the Thread Milling Product Manager for EMUGE Corp. in West Boylston, Mass. He can be reached at marlon.blandon@emuge.com

Recent Posts

KNOW the DRILL

Jun 1, 2023 9:51:31 AM / by Marlon Blandon posted in thread milling, Taps, Drill, Drilling

Three Reasons to Give Thread Milling a Chance

Jan 28, 2022 5:16:51 PM / by Marlon Blandon posted in Tool Holders, thread milling, Multi Thread Mill

Although EMUGE is known for its high-quality line of tapping products, there are times when thread milling is a better choice. In this post, we’ll explore a few of the key differences between the two, and when to use one over the other.

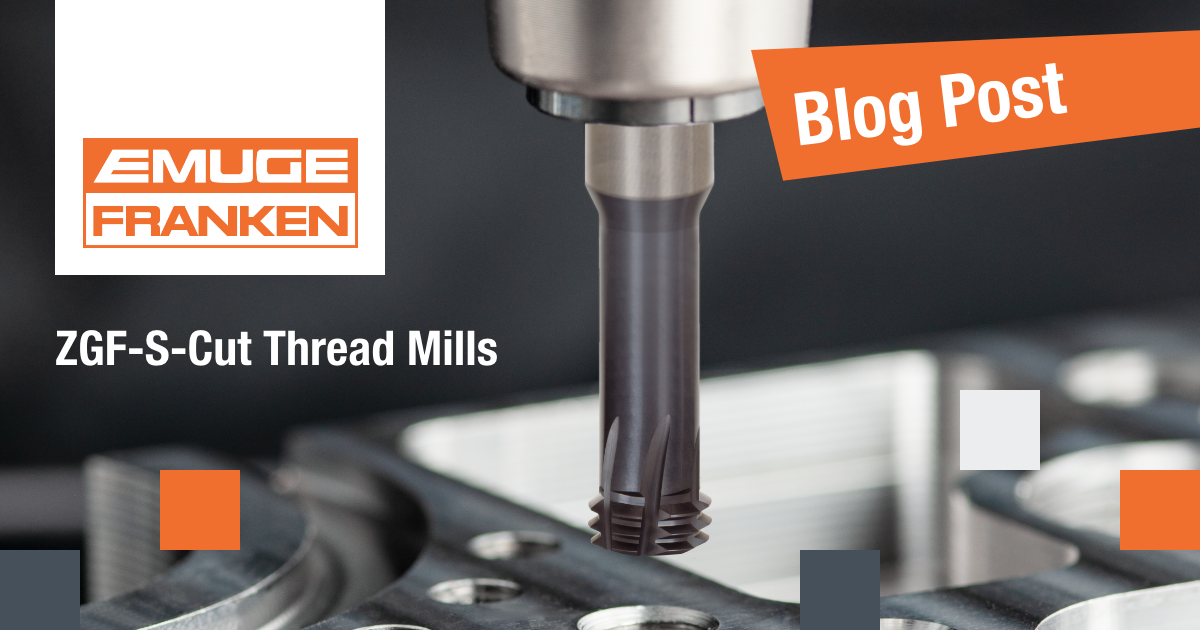

Achieving 10X Better Tool Life in Demanding Aerospace Applications with ZGF-S-CUT Thread Mills

Feb 10, 2021 1:11:24 PM / by Marlon Blandon

Materials that require threads to be thread milled (versus tapped) are usually very complex alloys created for components or parts designed for long term use.